Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Contact Us

Services

-

Products

- Diagnostic softwares

- Portable vibration devices

- Precision laser shaft alignment

- Termokamera, Hőkamera

- Ultrasound equipments

-

Vibration monitoring equipments

- Cables & Connectors

- Junction Boxes

-

Mounting Hardwares

- Accelerometer Installation Tool Kit

- Accelerometer Quick Disconnect

- Adhesive Mounting Pads

- Adhesives

- High Frequency Magnet System

- Motor Fin Mount Probe Pads

- Multi-purpose Rare Earth Magnetic Bases

- Probe Tips for Portable Measurements

- Rare Earth Magnetic Bases, Flat Surface

- Sensor Protector

- Specialty Mounting Adapters & Studs

- Online vibration monitoring equipments

- Signal conditioners

- Testers, accessories

- Vibration sensors

- Vibration protection

- Services

- Training

Viewed products

-

Infrared Thermography Services - Powerful, Versatile, and High Accuracy

The one of the bests and instant non-destructive...

Infrared Thermography Services - Powerful, Versatile, and High Accuracy

New

The one of the bests and instant non-destructive testing technology is infrared thermography. We are able to detect a wide range of problems and save a lot of time, energy and money for our clients. Detect problems with our service without big equipment investment!

- Elliminate electrical problems

- Bearing faults

- Compressors, turbines and other machine peoblems

- Processes monitoring

- Detect building insulation problems

- Energy optimatisation

- Electrical problems, box, switchboard monitoring

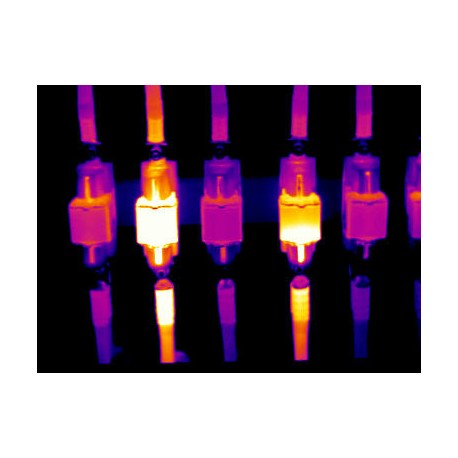

An infrared camera is a non-contact device that detects infrared energy (heat) and converts it into an electronic signal, which is then processed to produce a thermal image on a video monitor and perform temperature calculations. Heat sensed by an infrared camera can be very precisely quantified, or measured, allowing you to not only monitor thermal performance, but also identify and evaluate the relative severity of heat-related problems. Recent innovations, particularly detector technology, the incorporation of built-in visual imaging, automatic functionality, and infrared software development, deliver more cost-effective thermal analysis solutions than ever before.

Termography in architecture

Localisate the insulation problems with our thermography services. Heat-bridge, moisture and other problems caused by thermal differernces, heating and cooling loss can radically effect your buldings energy consumption. You can save a lot of energy and money if you can locate and repair the problematic areas. With our service it is quite simple and fast.

Electrical problems - Safety first

Electrical boxes, circuits, panels, chips thermography analysis, contact failures, closures, shaping problems, resistors assay with our thermographic services. With the ability in viewing small, irregular shaped objects and determining thermal characteristics and temperatures from safe distance, infrared cameras have been valuable assets to both production and diagnostic areas in the electronics industry.

Rotating machines, brakes, bearing problems

Breakdowns of machines and plants announce themselves with rising temperatures at an middle stage. With the help of thermography these critical areas can be detected without interrupting the power supply or the production process. Depending on the degree of damage it can be analyzed and fixed immediately or at a more convenient time. So measurements of e.g. rotating parts are possible in the majority of cases. Monitoring the condition of the plant continuously can avoid sudden breakdowns as repairs can be done prearranged.